PIANO TECHNICIANS……….BOTH

Mr. Bradshaw has been in the piano business all of his life. As a third-generation piano craftsman and technician, he began his apprenticeship at age 15 with his father who was a piano rebuilder, technician and Baldwin dealer for 54 years. Nine years of apprenticeship later, with a full knowledge of piano re-building and retail operations, Mr. Bradshaw began his lifelong piano career.

As the youngest Baldwin piano dealer ever accepted by Baldwin at the age of 24, Mr. Bradshaw began his career. He established Bradshaw's House of Pianos, the Baldwin piano dealer in Salina, KS. Mr. Bradshaw ran the retail operations as well as tuning for the local universities and music community. Being a pilot, he also traveled to many venues in western Kansas by plane.

Six years later, the opportunity arose to become the Shop Manager for a large piano rebuilding facility in Dyersburg, TN. This position entailed the overseeing of multiple brands of pianos being re-built in this factory-like facility. Each week, 3-5 grand pianos were refinished, all new parts installed, new strings, new felts, tuned and completed. From inexpensive grands to Steinway & Sons grands, all were rebuilt. Here, 10+ other piano craftsman and Mr. Bradshaw, produced up to 20 re-built, re-finished grand pianos per month. These were then wholesaled to piano dealers across 22 states. After 5 years in this position, the obvious choice was, new piano manufacturing.

In 1987, at age 32, the Baldwin Grand Piano Factory in Conway, AR., hired Mr. Bradshaw as the Quality Control Manager for the factory. He was responsible for all facets of grand piano quality for the 17 grands that were built each day by the 300+ craftsman workforce. From the raw wood coming into the factory to the final product shipped to Baldwin dealers worldwide, Mr. Bradshaw, his Quality Supervisor and his 12 Inspectors, kept the quality level at a world class level to compete on the world stage. The #1 and #2 competitors during this time, were Steinway & Sons # 1 and Yamaha # 2; the finest piano in the world and the largest selling piano in the world. Seventeen world class Baldwin grands were produced each day in Conway, AR. to compete with those manufacturers. In-factory training of new hires and re-current training of the factory's 300+ workforce, was under the Quality Department's duties also. It was at this time, 1987, that Mr. Bradshaw established Bradshaw Piano Service in Conway, AR. Tuning of the Univ. of Central Arkansas' 52 pianos, numerous music professionals and individuals, was done during the next 13 years, while also holding the Baldwin Factory's Quality Manager position.

Having spent the next 13 years as the Quality Control Manager of Baldwin Piano Co., he was then chosen by Baldwin in 2000, to become the Manager of Baldwin's Factory Store in Memphis, TN. Baldwin's factory retail arm was located 46 miles from the Baldwin upright piano factory. Newly designed or produced Baldwin product was first sent to the Factory store for evaluation and initial exposure to the public before shipment to Baldwin dealers nationwide. Mr. Bradshaw made numerous technical and sales evaluations to Baldwin Sales Headquarters, determining and recommending if the factory was going to produce these models. Mr. Bradshaw sold against all brands of pianos while managing the Factory store in Memphis. Learning about other brands' building specifications, their pros and cons, was very useful in expanding Mr. Bradshaw's knowledge of ALL brands of pianos and their quality levels.

After five years in Memphis, Mr. Bradshaw was hired as the Service Manager for the Steinway & Sons dealership in Little Rock, AR. Mr. Bradshaw's 30+ years of piano building at the Baldwin factory and rebuilding Steinway grands at rebuilding shops made him the perfect fit for Don and Gil Colaianni's Steinway & Sons dealership in Little Rock. Mr. Bradshaw was responsible for the pre-delivery prepping of all Steinway grands. Boston and Essex pianos, made by Steinway, were also made showroom ready. All field service work, tuning, regulation, voicing and Steinway Warranty work was either done by or supervised by Mr. Bradshaw. When a customer called the Little Rock Steinway dealer for tuning or technical work, Mr. Bradshaw was the contact.

After the retirement of the Colaianni's and subsequent closing of the dealership, Mr. Bradshaw returned to Conway to re-establish Bradshaw Piano Service. His un-matched experience in factory training, factory management, vintage grand piano re-building and retail piano experience, had made both his business and him, known throughout Arkansas. His excellent "Referral Letters" are a direct result of his having worked with the highest quality piano operations in the United States: a Steinway & Sons dealership, providing the excellent work one would expect from a Steinway dealership and in the manufacturing of world class grand pianos at the Baldwin Piano factory, overseeing all Quality.

Phyllis Bradshaw, has over 27 years of experience of piano production supervision at the Baldwin Grand Piano Factory in Conway, AR. During that time, she mastered all facets of piano construction and function. She worked as a craftsman and later in the Quality Supervisor position, over all departments in the 300 employee factory. The description, "Factory Trained", is a misnomer for Phyllis Bradshaw. Phyllis Bradshaw was the Trainer! She was the Baldwin Grand Factory instructor for all nine technical departments in the 300 employee factory. She was the factory trainer that taught Baldwin employees re-current training and trained new hires, how to build Baldwin grand pianos. This being done under her title as Quality Supervisor for the Baldwin factory.

In 2002, Mrs. Bradshaw became the Baldwin Polyester Finishing Factory Manager in Conway, managing 100+ employees. There, they applied the outside finishes to 10+ grand pianos a day. Her expertise in polyester, polyurethane and lacquer finishes, make her one of the top finish experts in the country! She claims 95% of the dealers in Arkansas as clients and routinely performs factory warranty work for Yamaha, Kawai, Steinway & Sons and others.

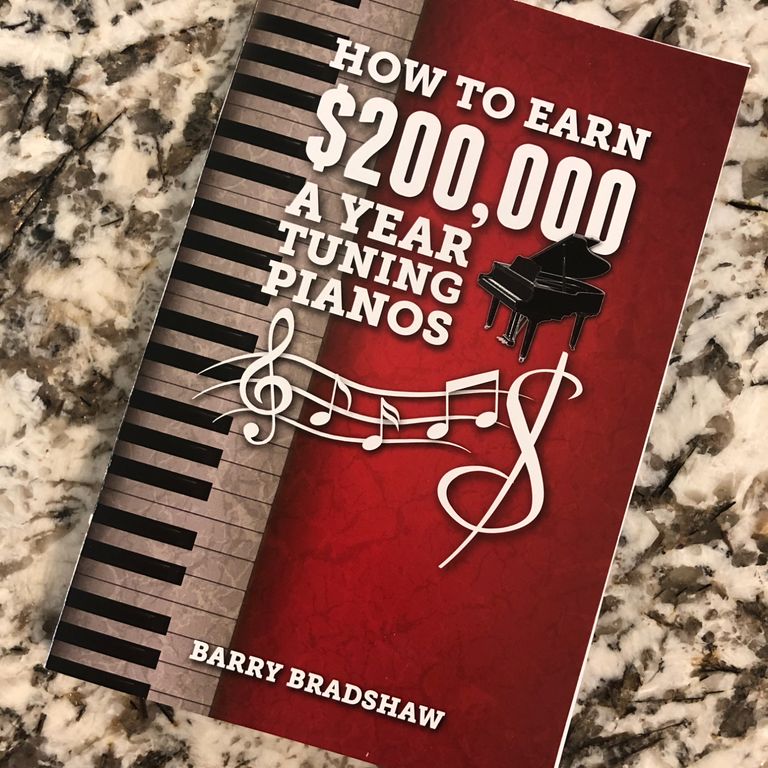

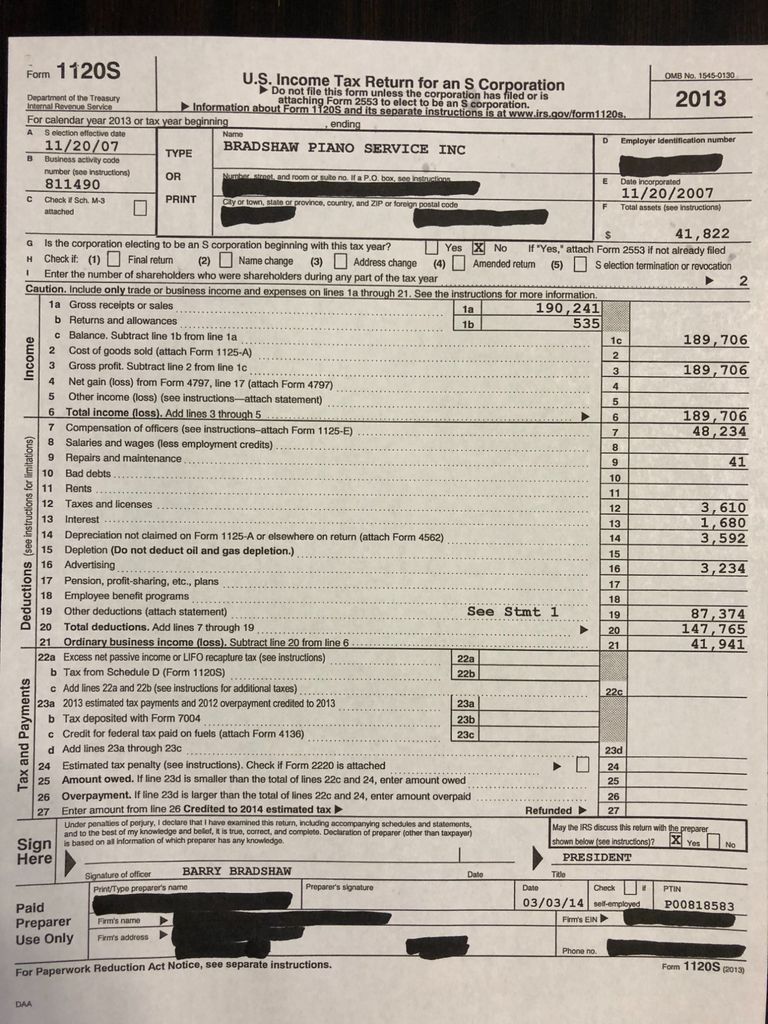

We have both manufactured new world class pianos at Baldwin's factories. We both were tasked with maintaining high quality to compete with Steinway & Sons. We both established and managed Bradshaw Piano Service, for 50 + years. I have tuned over 30,000 pianos in my half century career. I have worthwhile methods and strategies we have used to earn $200,000 per year. Here are my personal strategies, laid out in 1, 2, 3 fashion for you. You're going to get up each morning and tune pianos anyway! Why not earn MUCH more money while you are doing it?!

It COULD, change your life. Click on SHOP at the top of this page to purchase the book.

Not only can it be done; I have done $200,000 + for 15 of the past 16 consecutive years; save Covid 2020! It might take $30 bucks to acquire the information; but isn't it worth that? $200,000 a year, DOES put us in the Top 5% of piano technicians, in yearly earnings. It just takes the correct "proven" information and financial strategies. I have placed 50 years of them in this book for you and your family!

Click on SHOP at the top of this page to purchase the book.

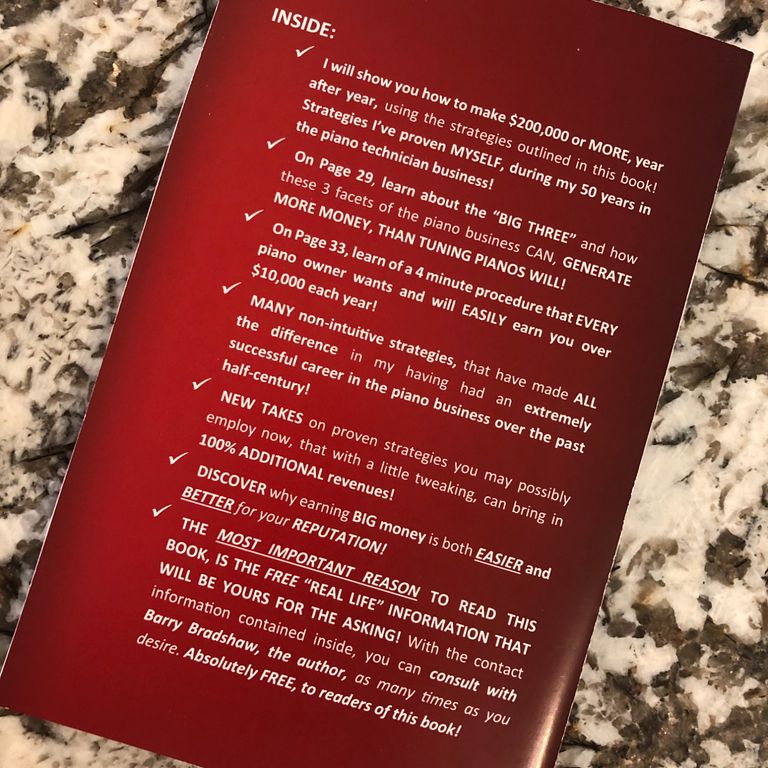

The "Most Important" part of the book?! The back cover, where I offer you, total access, not to just what's in the book, but to anything you ask of me concerning the piano business! As many times as you want, for as long as you want! INCLUDED, with the purchase of a book.

Click on SHOP at the top of this page to purchase the book.

$25 or $30 dollars, for information and strategies that can place YOU in the Top 5% of the highest incomed piano technicians. Why NOT you?! Why NOT your family?! You're going to work anyway; why not be one of the Top 5% earners in your profession?!

Hundreds of your peers and competitors, have purchased the book and learned these proven financial strategies of the piano tuning business. WHY not YOU? For just ... $30

Click on SHOP at the top of this page to purchase the book.